How to measure tire wear

Watch our step-by-step tutorial on YouTube.

Industry Standards recommends:

Replace your tire when it reaches 2/3 to ½ of the thickness.

How is this measured?

This 10” tire has 3 inches of tread, in other words, 1 ½ inch on each side. So if your tire’s overall diameter measures 8 ½ to 9 inches, that indicates that the tire needs to be replaced.

A good visual indication is when the wear on the tread reaches the lettering.

Other indications you might find are uneven wear where the tire is wearing more on one side than the other, cracking and splitting, and flat spots.

Replacing your tire will dramatically increase the life of your machine and minimize wear on other components.

When ordering tires, it is best to provide make and model. On older machines, depending on the manufacturer, you may also need to provide the dimensions of the tires.

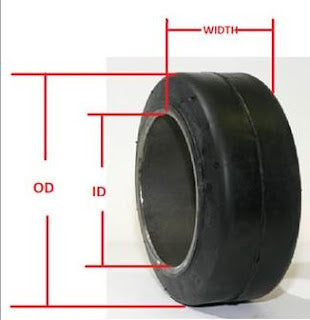

On solid industrial tires dimensions are typically given in this order:

Outside Diameter (OD) x Width (W) x Inner Diameter (ID)

Width of the Tire: Measure the width at the widest part, at the hub, because typically the tires are tapered.

For instructions on how to change your tire, please refer to the manufacturer’s manual.

We offer FREE tire pressing when you buy a new drive tire or hub.

We have over 200,000 new replacement parts for

and more